According to Bottled Water Organization, Americans will consume up to 15 billion gallons of bottled water in 2020. This shows how people rely on and trust bottled water. But have you ever wondered how are bottled water made? Let’s dig it in depth and find out how it actually is produced what you keep drinking daily!

What Is Bottled Water?

Hardly there would be a person these days who may doesn’t know about bottled water these days.

Bottled water is different from ordinary tap water, processed and made through complicated cleaning and chemical procedures.

The aim is to provide the human body with healthy water that contains minerals that are beneficial for your body.

Minerals like magnesium, calcium, potassium, etc., are added to water bottles to improve water quality and raise your living standards.

Nowadays, almost more than half of the world’s population knows and drinks water from these plastic water bottles containing purified water. That’s just a brief description. You can learn more about bottled water in our bottled water-ultimate guide, which provides detailed information on this topic.

How Is Bottled Water Actually Made?

It’s true that to understand the importance of bottled water, we must know how it is made and purified so that we can take some healthy, fresh, and natural sips of water. In short,

In water purification applications or mineral bottled water production, three methods are usually used: Deionization, Distillation, and Reverse Osmosis. But most bottled water is produced with the Reverse osmosis method as it is relatively cheaper and provides water with more effective cleaning in a short time.

But since you are here, you will learn about all these methods one by one and know which one is better from these and why.

How Is Bottled Water Made Through The Process Of Deionization?

It is probably one of the most classic methods to filter out or purify water for drinking. The deionization method of filtration for water means removing all dissolved salts from the water.

It is done by passing the water through two ion exchanging materials so that they may prove effective in removing the salts from the water.

This whole process is based on two stages.

The First Stage:

The water bottle manufacturers often called the Deionization method of water filtration demineralization.

Because here, in this process, the normal water softening removes the magnesium and calcium ions from the water when it passes through those chemical materials.

There will be no sodium ions because the other positive metallic ions will be removed and fully replaced with hydrogen ions.

When such ions exchange with themselves, there will be a balance of electrical charges. The solution will become very acidic as there will be more hydrogen ions in the process.

The Second Stage:

In this stage, the partially treated water passes through the second unit, and the negative ions in the water are exchanged and absorbed into the anion exchange material.

You will get the hydroxyl anions released in this result.

When these two stages get completed, you get ion-free water. Ultimately, when the hydrogen ions also get settled, you will get mineral-free water packed in a bottle.

Hence, the deionization process produced mineral-free water, which is not usually acceptable.

Because what we drink is full of minerals, let’s go for the next step to find out if it provides us with the needed water.

How Bottled Water Produced Through The Distillation Process?

This is the second most commonly known method of producing bottled water.

The distillation process is as simple as this; the impurified water is boiled in a large boiling chamber until the last moment, evaporates into the steam.

This steam is then captured and condensed in a separate purified and clean container.

Overall, the distillation process of water purification is based on the following steps.

Heating The Water:

At first, there comes a boiling chamber in which the water is heated. It shall be heating up to the point when the water starts having a rolling boil.

This rolling boil produces evaporation as well as steam production.

Capturing The Steam:

When the last thing happens, this produced steam rises in a vent of the chamber or through any stainless steel condenser.

At that moment, the boiling chamber will have all those microorganisms, impurities, or other containments that didn’t convert into the gas partials.

Conversion Of Steam Into Water:

When steam gets condensed and reaches the upper side condenser, it gets chilled with the help of a fan.

The chilling process continues until the steam returns and turns into water droplets. You can collect these droplets in a clean container.

However, a final filtration stage should still be kept in mind.

Usage Of An Activated Carbon:

If there are any impurities in the water, these will be removed.

In most conditions, activated carbon is used to remove, filter out and tap these impurities through absorption.

Water Is Read To Be Used:

This final step collects the water in a clean container or water bottle. This happens when the water passes through the filtration media and drips into that distiller’s spot. From there, it goes into that cleaned holding container.

Congratulations, the water is ready to be used and drank for any purpose because it is clean, pure, and safe.

Hence, these are all the steps or things to be done in producing water through a distilled water production process. Read more about the Water and Waste Digest organization to get in-depth details.

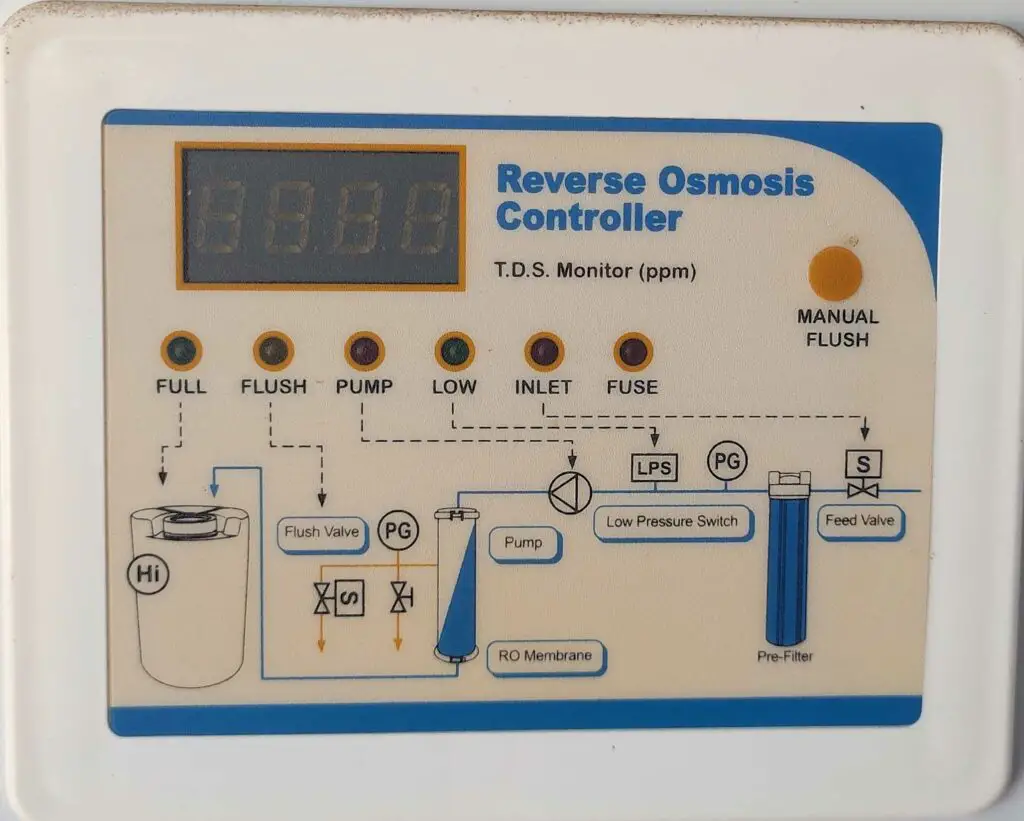

How Bottled Water Produced Through The Reverse Osmosis Process?

Finally, I will explain the highly known and widely used method for bottled water purification, the Reverse Osmosis Purification of water.

It is considered one of the easiest and cheapest water manufacturing companies.

Because the method doesn’t involve so many complications, one time, a company needs to set up a purification plant for it. And for years to years, it can produce tons of bottled water with that plant.

Back in those days, the reverse osmosis purification process was highly known and used by the US Navy to filter out water and provide it to the crew members.

These days, many consumers are highly attracted to this water purification method.

The basic reason is not only that the process has much fame, but the water produced through it has the lightest, sweetest, and most refreshing taste.

A reverse osmosis water purification process is based on the following steps. Please have a look!

Determining The Source Of Water:

At first, the source of water that needs to be filtered out is determined. These water purification plants are placed in areas with more water in the ground and at the nearest level.

Plus, these might also be placed near a sea, river or pond where there is no need for water transportation to make it a source.

Sending The Source Water In A Pre-Sediment Filter:

The water coming from the source is sent into a pre-sediment filter where its earlier sediments and solids are removed.

After that, the water passes through two pre-carbon filters that ensure that there shall be no chlorine mixing or any taste and odor remaining in the water.

But that’s not the final cleaning. It yet has to happen.

Water Passing Through An Intense Reverse Osmosis Filter:

From the previous stage, the water goes into another, called reversed osmosis filter. This works at a very high speed and in a reverse direction.

Such speed proves a great source of removing almost 99% of the remaining impurities from the water and making it clean.

Protection Of UV And Ozone:

After passing through the reverse osmosis filter, the water gets treated with UV light and ozone treatment.

Once done, your water is cleaned, purified, and ready to go into the water bottles. These water bottles get supplied to different regions or towns wherever acquired.

Overall, these 4 steps define the reverse osmosis process and how water gets cleaned through it.

So, these are the top three most basic methods of cleaning water and making it purified to drink.

What Are Things Required Before The Production Of Bottled Water?

Producing a large quantity of bottled water is not very difficult if you know exactly how to do certain things. Some things will be needed, some rules that should be kept in mind, and procedures to adopt for building bottled water. These are all stated as follows.

The Guidelines Drawn By The FDA:

Your water purification system or plant shall be constructed after agreeing with all the rules, regulations, or guidelines imposed by the FDA.

They have vast definitions of the things, including those bottled water manufacturing practices, meeting the exact quality standards, having better sanitary facilities and more managed operations, regular and correct labeling, as well as inspection and those multiple controls plus quality production processes.

Moreover, at some points, the states will also impose rules and regulations that will vary from one state to another. But whatever you produce must always meet the industry standards.

However, some bottled water manufacturing companies can also make their own rules. But these rules or guidelines must be approved by the FDA.

The Right Source From Where Water Shall Be Taken:

It doesn’t matter which water cleaning or filtration method you use to produce bottled water, the source of water from which it is always coming matters.

It will be something that will decide the taste, quality, and other features of the water you will produce.

Therefore, always choose a source of water that is easily accessible, could be tested and proven safe from organic and non-organic compounds, and meets the standards that such water can be further filtered out.

Otherwise, you may not be able to produce bottled water which is highly admired by many individuals who drink it daily.

The Usage Of Right Equipment:

We are pretty sure that we don’t want to produce water that would be smelly, not cleaned or cleared, and has a weird taste.

This might be happening due to the presence of metallic ions or organic compounds present in such water.

However, to do that and achieve maximum satisfaction with this water, we need some equipment working on our site to do.

Filtration usually comes by applying one of the methods mentioned above. But to reiterate, you can do the following things.

Usage of membrane filtration-This equipment can easily remove those organic impurities, including metal and similar ions.

Ozonization-It can easily break down those organic constituents and help you in giving a better taste to your filtered water by removing its smelly odor.

But it doesn’t matter whatever is used; the plant will be built using all the tools and equipment it needs to produce pure, clean, healthy drinking bottled water.

How Many Types Of Bottled Water Are There Based On Labeling?

Usually, there are two types of water after a filtration process: Purified Water and Spring water.

However, they may taste the same, but the filtration process could be different.

On the other hand, the FDA imposes the water bottle manufacturers to put a certain label on the bottled water so that a customer may easily be able to recognize it.

These highly known labels for bottled water are given as follows.

The Spring Water:

Such a label on bottled water indicates that the water inside has come from a natural underground water source.

This type of water is collected at the spring or a borehole.

You may see it in the farms where they have tube wells to provide water to the corps, and often these boreholes were found in many homes in the classic times.

Artesian Water:

This water is named Artesian water because it is present in the protected underground source.

For instance, the water coming from any artesian aquifer is the water that comes out without the need or necessity of using a pump.

Mineral Water:

A mineral water label on a bottle of water means such water is also coming from an underground, protected source. There is no need to treat it. Because it is already enriched with many healthy minerals.

Purified Water:

It can be any water produced by any purification method. It can also come from any municipal source.

Or even through a well as well as other public water supply. They sent it to your house after removing all the impurities and filtering it out completely.

The Sparkling Water:

When any spring or a well provides water with a dissolved mixing of Carbon Dioxide, it is called sparkling water. You can also name it naturally carbonated water.

Table Comparison Of Different Types Of Waters Available With Their Reliability:

| Type Of Water | Source | Needed To Filter Or Not? | Is It Available? | Reliability |

| Spring Water | Coming from the underground source | Not necessarily if the source is cleaned and natural | Yes, at many stores and provided by many brands in the USA | Very reliable to drink |

| Artesian Water | Water coming from any aquifer | Not really because it is the natural water available | You may find it or may not | Good to drink without any fear |

| Mineral Water | Coming From The Ground | Contains a large number of minerals considered safe for health. But it must always be tested before bottling it. | Yes, at many stores and is provided by many brands in the USA. | Excellent to drink and healthy for your body. |

| Purified Water | Comes from the municipal or any local water provider. | Yes, it requires a huge cleaning process to filter out all the impurities. | You can find it anywhere in the form of water bottles at any nearby store | Good To drink |

| Sparkling water. | We actually name It carbonated water, | Yes, it can be filtered out if needed. | It can also be found only in a few stores in the united states. | Good To Drink |

How Much Does It Cost To Build A Water Bottling Plant?

You might want to build yours if you know all the chemistry and have experience working in any bottling water plant.

It is not difficult. But the cost that would require for it will be approximately $750,000 and even cost up to 1.5 million USD and even more when the intensity of work and operations increases.

Moreover, these costs will also rise when you have to go for a registered and approved FDA permit or your State Health Department.

Final Thoughts:

Bottled water can be produced in many ways, such as carbon filtration, Ion Exchanging, Microporous Basic Filtration, and even Ultraviolet (UV) Radiation. But the best are only the ones I have explained in this article. So, I can be hopeful that you have all the information on how bottled water is made. However, you are most welcome if you still have something to ask.

Thanks for reading and giving your precious time. Drink healthy and stay healthy. See you at the next one!

References:

- admin (2015). Reverse Osmosis Water Process. [online] Distillata. Available at: https://distillata.com/blog/what-is-reverse-osmosis-water/

- www.freedrinkingwater.com. (n.d.). Water quality information – Water Deionization Process Explained | APEC Water. [online] Available at: https://www.freedrinkingwater.com/water-education2/49-water-di-process.htm

- www.freedrinkingwater.com. (n.d.). The Bottled Water Purification Process Explained| APEC Water. [online] Available at: https://www.freedrinkingwater.com/water-education3/31-water-bottled-water-purification-process-page2.htm.

- www.wwdmag.com. (n.d.). StackPath. [online] Available at: https://www.wwdmag.com/editorial-topical/what-is-articles/article/10940138/what-is-water-distillation.